Video: How to Notch a Neck for a Neck-Through Cigar Box Guitar

In this video, Glenn Watt walks you through notching/recessing a neck so it will fit properly into a cigar box guitar.

The How-To Repository for the Cigar Box Guitar Movement!

How to Build and Play Cigar Box Guitars and other Homemade Instruments

Here is our library of How-To information specific to building cigar box guitars. Browse all articles below, or choose a subcategory:

· Design and Decoration

· Electronics, Pickups and Wiring

· Fretting

· Necks & Headstocks

· Other Hardware How-To

· Tuners

· Tunings and Strings

In this video, Glenn Watt walks you through notching/recessing a neck so it will fit properly into a cigar box guitar.

In this excerpt from a Cigar Box Nation TV episode, A. J. Gaither and Ben “Gitty” Baker discuss two great tenor guitar tunings for 4-string cigar box guitars: “Arkansas Tenor” (low E, A, D, G) and “Chicago Tenor” (D, G, B, E). Both allow you to use partial 6-string guitar chords – Ben even shows you how to use 6-string chord forms with both of these tunings.

In this excerpt from a Cigar Box Nation TV episode, A. J. Gaither and Ben “Gitty” Baker discuss two great tenor guitar tunings for 4-string cigar box guitars: “Arkansas Tenor” (low E, A, D, G) and “Chicago Tenor” (D, G, B, E). Both allow you to use partial 6-string guitar chords – Ben even shows you how to use 6-string chord forms with both of these tunings.

Cigar Box Nation TV is a presentation of CigarBoxNation.com, the online home and rallying point of the cigar box guitar revolution. It is sponsored by C. B. Gitty Crafter Supply, the general store for all things cigar box guitar and homemade/handmade music – instruments, kits, parts and gear.

In this article we will show you the differences between mono and stereo output jacks, and how to wire them for use on your cigar box guitars.

A lot of folks have questions about wiring jacks: how do you tell mono from stereo, which lug is positive and which is negative, and can you use a stereo jack with a mono cable (the answer is YES, you can – see the final paragraphs below for how).

This article covers “phone” style jacks, which are made to be mounted in a panel via a threaded shaft and nut, with the soldering lugs for attaching wires extending off of the back. They also have one or two “prongs” that stick off of the back and make contact with the tip of the plug.

First, let’s take a look at the differences between a mono an a stereo jack. These photos show the popular Neutrik/Rean brand phone jacks, but these principles apply to jacks from other manufacturers as well

So you can see that the stereo jack has one more solder lug and prong than the mono jack does. This is because to have stereo sound, you need both a left and right channel (so that you can hear different things out of the left and right speakers of your stereo) plus the ground. A mono jack only has a single channel plus the ground, for handling mono sounds – like what guitar pickups put out.

Here is a close look at the mono variety of phone jacks. Click on the photo for a higher resolution photo.

Here is a close look at the mono variety of phone jacks. Click on the photo for a higher resolution photo.

Notice that the longer lug, which if you look closely in between the yellow wafers is connected to the long prong that sticks out of the back, is the positive. The shorter lug, which is connected to the “sleeve” part of the jack which touches the “barrel” of the plug, is the ground/negative.

This is the standard style of jack most often used when installing pickups in cigar box guitars. They are also often used as input jacks on mono amplifiers and other audio equipment.

You can buy these exact Neutrik/REAN brand mono jacks here on CBGitty.com.

We also have “economy” grade mono phone jacks available here, if you want to save a little money.

Now for a closer look at the stereo variety. Click on the photo to the right for a higher-resolution version.

Now for a closer look at the stereo variety. Click on the photo to the right for a higher-resolution version.

The stereo jack has the extra lug and prong mentioned above, but otherwise is very similar to the mono jack. If you hold a stereo jack like the one shown in the photo, then from left to right the lugs should be Positive Left, Negative/Ground and Positive Right.

You can verify this by looking carefully in between the yellow wafers that make up the body of the jack. The lug that connects to the longer prong (#3) is the right channel positive. The lug that connects to the shorter of the two prongs (#1) is the left channel positive. The lug that connects to the sleeve that touches the “barrel” of the plug (#2) is the ground/negative.

Now let’s take a look at how they look wired up.

As always, RED is POSITIVE and BLACK is NEGATIVE/GROUND!

The photo above shows how you would wire both jacks for MONO use. Note that lug #1 on the stereo jack has no wire soldered to it. In this configuration, both the mono and stereo jacks could be used on a cigar box guitar with a standard mono amp cord. Once installed no one would be able to tell that it is actually a stereo jack.

If you wanted to wire the stereo jack for actual stereo usage, you would simply solder on another positive lead to lug #1. Some builders sometimes do this if they have more than one pickup in their guitar that they want to hand off to a special amplifier setup, but that is a more advanced topic we don’t need to get into here.

So that’s about it! We hope this article has helped clear up any confusion you may have had about how mono and stereo jacks work, and how to make use of them.

Zero frets are an awesome addition to any cigar box guitar or other homemade/handmade instrument builder’s toolbag. In this how-to article, C. B. Gitty walks you though zero frets on cigar box guitars: what a zero fret is, why you’d want to use one, and how to go about installing your first one.

The Zero Fret is an arcane subject to many cigar box guitar builders. I have to confess, for a long time they were a mystery to me too. Sure I had heard of them, seen pictures of people using them, and thought I understood most of the concept – but for some reason, I still always shied away from using one. That is, until Shane Speal finally beat it through my stubborn skull that we needed to start using them in the C. B. Gitty shop, and once we tried it we didn’t look back.

So this article is my effort to help everyone realize the benefits of using a zero fret setup on their cigar box guitar builds. It may not be for everyone, but my hope is that you’ll consider giving it a try. I’ll break this article down into three clear sections: What is a Zero Fret; Why to Use a Zero Fret; and How to Install a Zero Fret.

Most simply stated, a zero fret is an extra piece of fretwire, usually a couple of sizes bigger than what you’re using on the rest of the fretboard, which gets installed up at the top of the fretboard where the nut would usually go.

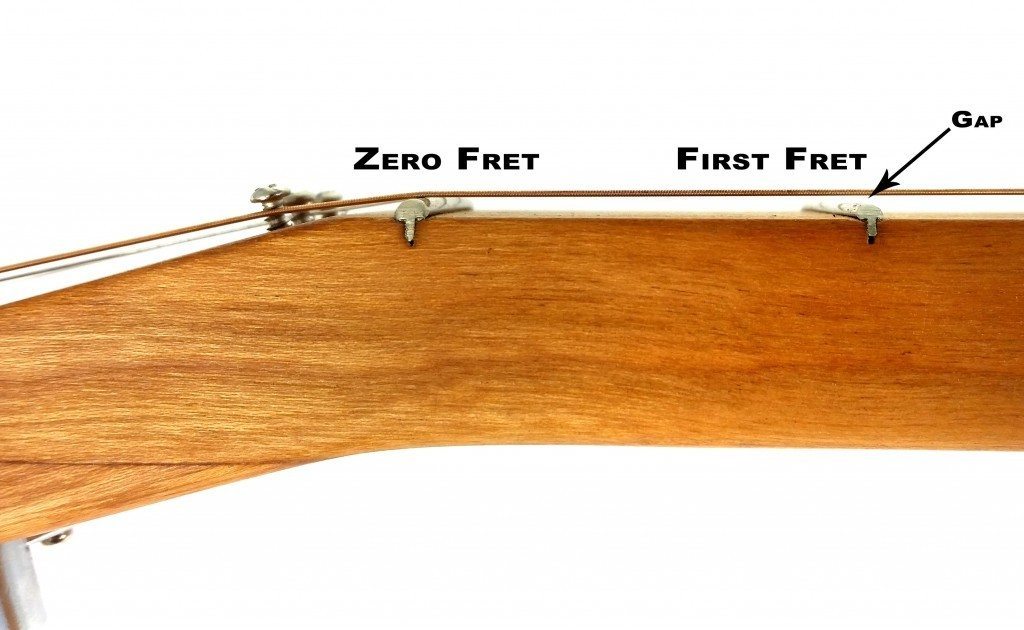

In our workshop, we usually use either our Medium/Medium nickel-silver fretwire or our Medium/High nickel-silver fretwire on the instruments we build. So for our zero frets, we will use a larger fretwire, most often our standard Jumbo nickel-silver. The jumbo wire’s crown is about 0.014″ higher than the Medium/Medium, and 0.012″ higher than the Medium/High, and we feel that this helps make sure that the action height work better and minimize buzzing in the strings. Other builders use the same size fret wire for the zero fret as they do for the rest of the frets. Check out the photo below.

In the photo you can clearly see that the zero fret is a larger profile than the first fret (jumbo vs. medium), and you can also see the effect – a pronounced gap between the strings and the first fret. This gap is what is technically referred to as the “action” or “action height” of the guitar, and keeping it as low as possible is very important to having a well-made and easy-to-play cigar box guitar. As mentioned above, some builders prefer to use the same size of fret wire for the zero fret as they do on the rest of the fretboard – it’s not what we do, but there’s no question that it can work just as well. We advise trying both and seeing what works for you!

The other things you can see in the above photo are small screws that are used as string retainers, to make sure the strings stay in the right places , and at a good angle, as they cross over the zero fret. More on this below.

As mentioned above, to build a fretted cigar box guitar that a professional musician will want to play, you have to pay very close attention to the “action height” – that is, the height of the strings off of the frets. You want it to be as low as possible, but not so low that you get buzzing or rattling from the strings when played.

Traditionally, the job of determining the action height on a guitar is done by the nut. Most often on store-bought guitars, nuts are made from bone, but they can also be made from plastic, wood, metal or synthetic materials like Corian.

The nut is glued into place at the top of the fretboard, and filed/sanded down to the right height, and then grooves for the strings are filed in to help keep the strings in the right position. As such, the nut both sets the action height (the height of the strings off the frets), as well as setting the spacing and position of the strings across the fretboard.

The problem with a nut is that it takes some skill and finesse to get them shaped just right, and at the right height, and with the string grooves just so. Of course if you file it too far down, there’s no going back – you have to remove it and start over with a new one. It is just way too easy to end up with an instrument with high action, which is not very fun to play and may even intonate badly, when using nuts.

Enter the Zero Fret – when you use a zero fret, you are pretty much guaranteed that your action height will be pretty much perfect. A good rule of thumb concerning action height on a guitar is that the gap between the strings and the first fret should be about 0.80mm – which just happens to be the thickness of a standard medium guitar pick. If you use jumbo or even one of the higher-profile medium gauges as your zero fret, and one of the standard medium-height fret wires (around 0.040″ to 0.045″ crown height) as the rest of your frets, you will definitely be in this ballpark.

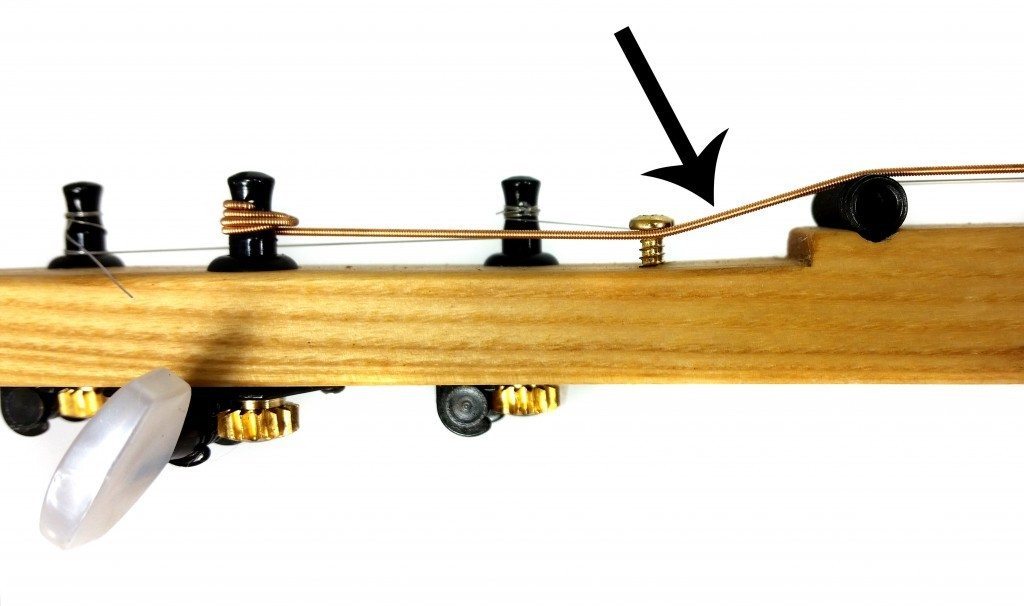

One caveat with a zero fret is that you do need to install some hardware to help keep the strings in place. Depending on your headstock design (angled verses recessed) this hardware might also need to serve the task of holding the strings down, so that they will have some “break angle” as they go up and over the zero fret. See the photo below for a visual of what break angle is.

There are various styles of string retainers that can be used for this, but on C. B. Gitty cigar box guitars we usually use small round-headed screws for this purpose (as shown in the photos above and to the right).

Assuming that you have read everything above, there shouldn’t be too much mystery left as to how you should go about installing your first zero fret on a cigar box guitar. Here is the outline of steps to follow:

You should now be able to string and tune your guitar, and your zero fret should be giving you pretty much optimal action height. The added step of having to use string retainers is a small price to pay compared to the hassle of installing and filing down a nut and getting it just right.

Zero frets, properly used, guarantee good string action height every time, and at least in the C. B. Gitty shops we have switched over to them for pretty much all of our Farmington Road Instrument Works cigar box guitars.

I hope that this article helps you better understand what a zero fret is, why you’d want to use them, and how to go about doing so. Please feel free to post comments or send questions, so that I can revise, expand and add to this article!

In this post, you’ll learn a terrific way to drill holes for cigar box guitar (CBG) tuner bushings from a video recorded by CBG community member Marty Tauber. Continue reading “[VIDEO] Cigar Box Guitar Tuner Bushing Drilling Tutorial”